Impact sound insulation

Active principles

The impact sound is emitted in the receiving room as airborne sound. The impact sound level (L) is an absolute value. Specifically, this means that a lower impact sound level equals better impact sound insulation. (The opposite applies for airborne sound insulation: the higher the apparent sound reduction index, the better the sound insulation.)

Technical building installations

Structure-borne noise is also caused by building technology. Everyone is familiar with the sound of sanitary facilities, ventilation systems, washing machines, and other household technology. Again, the noise that they make can be counteracted by decoupling the source of structureborne noise in order to reduce the transmission of noise to other components. In the case of a washing machine, for example, the easiest way to achieve this is to place an elastic underlay below it. For pipes and fittings, the following applies: the heavier the wall to which they are attached, the lower the noise level.

The main measures for protecting against impact noise

- Decoupling the systems e.g. with floating screed. Assumes that there are no rigid connections between the screed and the primary structure of the building.

- Generally avoiding sound bridges

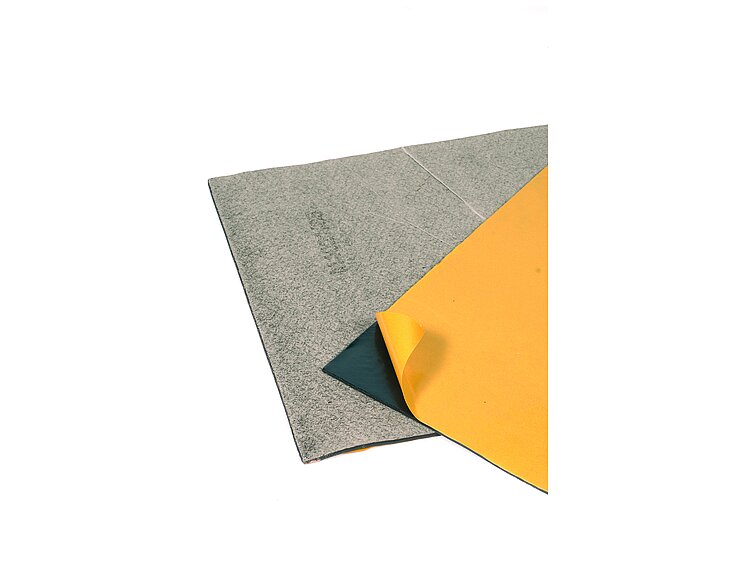

- Impact sound insulation mats

- Carpets and other soft or yielding floor coverings (linoleum, vinyl tiles, etc.)

- Minimising flanking

- Airtight joints

- etc.

In practice

Wooden beam ceilings in old buildings usually have poor insulation properties for impact and airborne sound.

On renovation projects, it is important to consider the loadbearing capacity of the beams and the maximum possible construction height. Cement screeds tend to be unsuitable for weight and construction height reasons.

With dry constructions weighted down with Idikell, sound insulation can be improved effectively at a low construction height and mass. Further improvements seen from the top of the ceiling are possible by covering the panelling of the bare ceiling with one or two layers of Idikell.

On the bottom side, a suspended ceiling decoupled with AmpaphonZ 600 and weighted down with Idikell improves the sound insulation considerably. Cavities should be filled with insulation featuring high flow resistance.

Floating screed

23 Airtight layer Ampatex DB 90

50 Anti-sound coating / heavy foil Idikell M 4001/05

60 Edge adhesive Ampacoll RA

73 Chipboard

80 Impact sound insulation

81 Cavity insulation

83 Permanently elastic cemented joint

84 Lining

87 Sliding floor

88 Floating floor covering

89 Slag

90 Formwork

91 Felt underlay

Nice to know!

Provide circumferential joints from 7 to 10 mm. Seal the joints with a suitable sealant. Ensure full air impermeability. It is not advisable to use synthetic insulation materials for sound insulation. Mineral wool with a density of at least 50 to 60 kg/m3 is recommended. For ceiling installation, use edge strips (e.g. Ampaphon Z101) where possible. An airless, nonventilated space in the structure is the best place.