Interior Finishing

Why build an airtight house?

These days, clients have high demands for the quality of their own homes. In particular, they pay special attention to their living climate: It has to be comfortable, on no account should it be too damp or too dry and the energy costs must be kept within reason. In other words: Everything should be right, with no ifs or buts. Which is one more reason why the construction of new buildings should always be airtight.

Build well, build airtight

Heat loss due to a lack of airtightness is energy intensive and can potentially cause great damage. The installation of a high quality airtight layer protects both your wallet and the value of the building. The amortisation of the investment over many years is clearly more relevant here than the short-term cost considerations.

The concept of the «breathing house» has long been the stuff of fairy tales. Ventilation, air exchange and humidity control are not regulated by the walls or even the building shell, but exclusively via doors and windows or by a corresponding air intake and extraction system. What is fatal: even the smallest joints and tears in the building shell can cause disastrous amounts of damage to a house and result in clearly escalating energy costs. These are all factors that can cost the owner not only a great deal of money but also time and nerves.

In the case of new buildings a permanent, airtight layer has been a statutory requirement for many years now.

8 good reasons for an airtight building shell

- No draughts

- Less heating energy consumption

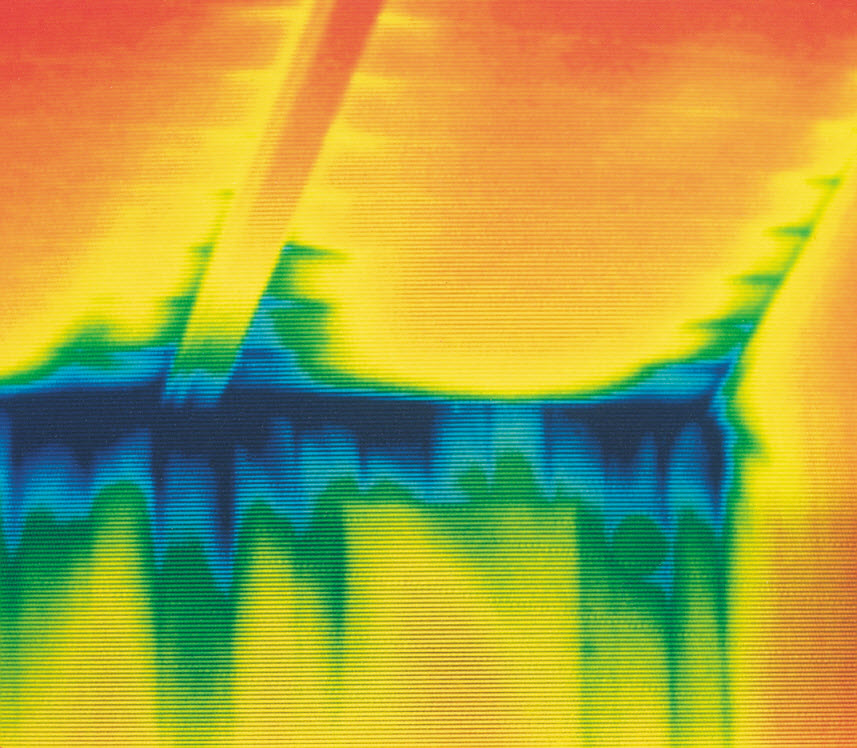

- No condensed water in the construction

- No mould formation

- No damage to the building

- Clear improvement in the quality of air in the rooms

- Clear improvement in sound insulation

- Ventilation systems work highly efficiently

Avoid construction damage, maintain indoor comfort

A building is more than the sum of all the individual products used

Planning mistakes are the main reason for building damage. They often occur at the beginning of a project. In particular in cases where the client’s wishes for an all too «economic» solution to the building costs are observed. Faultless construction always begins with thorough overall planning. Only when all the individual factors for a building have been taken into consideration in the project planning is the way clear for the minimisation of any damage in the overall construction. Carry out this overall planning by means of a realistic budget, correct execution and permanent controls.

In order to avoid possible mistakes or even damage during a building project, you should ask yourself the questions on the right side in advance. New designs and building products are constantly being launched on the market and this makes it difficult for builders to maintain an overview and to familiarise themselves with the correct application of the products.

Ampack offers you not just the products but also a full package to go with them to ensure the airtight construction of the building shell.

Important questions

- Have you factored in the different installation levels?

- Have you chosen all the products that you need for the project correctly?

- Are you sure that the specialists who will be carrying out the work will work together professionally; that they will communicate correctly with each other?

- Have you addressed the matter of building moisture?

- Have you guaranteed that the tightness was checked using the differential pressure drop method in good time before the assembly of the interior lining?

Eliminate the potential for damage

The costs of airtightness with Ampack products for a house with a floor area of 10 × 14 m

Saving money on the products and processing can cost you dear in the end. Heat loss due to ventilation caused by a lack of airtightness are energy intensive on the one hand and on the other hand they can potentially cause a great deal of damage. A high quality airtight layer protects both your wallet and the value of the building. It is particularly important here to pay attention to the amortisation of the investment over many years and not to be swayed by short-term cost considerations.

If the costs of an airtight building shell are calculated based on a single family dwelling with a floor area of 10 × 14 m, it soon becomes clear that the material used forms only a small proportion of the cost.

If cheaper products were used, let’s say at half the price, the total savings would come to 613 Euro, calculated at gross cost. In relation to a single family dwelling worth EUR 350,000, this comes to a mere 0.18 %. This in no way reflects the additional costs that would be incurred by possible damage to the fabric of the building by neglecting to install an airtight layer. And it is impossible to calculate the health risk to the whole family caused by draughts and mould.

| Product | Quantity | Cost per unit in EUR | Total cost in EUR | |

| Element walls | Vapour retardant Ampatex DB 90 | 300 m2 | 3.25 | 975.00 |

| Steep-pitched roof | Vapour retardant Ampatex DB 90 | 150 m2 | 3.25 | 487.50 |

| Adhesive technology | Ampacoll INT, overlaps | 450 running meters | 0.85 | 382.50 |

| Ampacoll RA, edge connections | 1 cartridge | 11.90 | 11.90 | |

| Ampacoll BK 535, penetrations | 10 running meters | 4.17 | 41.70 | |

| Ampacoll FE, window connections | 25 running meters | 2.37 | 59.25 | |

| Ampacoll Primax, primer | 1 tin | 27.50 | 27.50 | |

| Total cost of materials | 1’985.35 | |||

| Total installation costs | 450 m2 | 12.00 | 5’400.00 | |

| Total airtightness costs | 7’385.35 |

Planning

Good planning means that mistakes in the construction and the ensuing extra costs can be avoided. The points on the right side form the foundation for an airtight building shell.

A systematic approach to the use of vapour retardants and vapour seals is a prerequisite for the correct functionality of the layers used.

- Include the different installation levels in your planning

- Choose the correct products

- Information and coordination of the specialists carrying out the work

- Take any trapped moisture into account

- Check the airtightness using the differential pressure drop method before the assembly of the interior lining

Surface installation

In many respects, vapour retardants fulfil the function of the airtight level. They are generally positioned on the warm side of the construction. If they are fastened as tension-free and with as few creases as possible, suction and load effects on the areas of adhesion and connection can be avoided. This helps to avoid the splitting of the membrane where it has been stapled and/or rupturing at the edge connections. Adhesive strips, liquid adhesives, etc. safeguard the airtight layer but do not act as a mechanical fastening. Dirt and dust on the surface of the membranes can radically reduce the adhesive qualities of even the best adhesives. In order to ensure that the membranes are completely airtight, they must be bonded as soon as they have been placed in the area of overlap. Ideally the overlaps are bonded from the centre of the room towards the edges, in order to minimise the risk of creases.

Edge connections

Once the airtight surface installation has been completed, the edge connections are also made airtight. The adhesives for the membrane being used and the surface to which it is bonded must also be compatible. The surface must be prepared carefully. All surfaces must be dry and free from any dust, ice or grease. Porous and sanded surfaces must be pre-treated with primer. The use of today’s liquid adhesives makes mechanical stapling unnecessary. However, the norms that apply here must always be observed.

Penetrations

Including the different installation levels in your planning makes this task much easier. The same care and attention to the surfaces is required here as with the edge connections. Any damage to the airtight level must be repaired. The construction manager must ensure this is carried out and check the results.

Board materials

Additional measures are required to make boards airtight

Plasterboard and fibre cement panels, metal sheeting and wood-based panels must be bonded in accordance with the norms to ensure they are airtight. Separate measures must be taken to deal with joints, connections and penetrations. Ampack offers a comprehensive range of adhesive programmes for the airtight bonding of board-like materials that take account of issues to do with timber house construction: good adhesive qualities for all wooden materials, appropriate primers where necessary, flexible strips for internal and external use.

Note

The best airtight layers, vapour retardants and sealing products cannot prevent leakages from having negative consequences. These can be caused by the incorrect sealing of overlaps and joints or the inexpert sealing of connections and penetrations, for example. Damage to these layers will also result in convection. This means that moist room air is sucked into the construction and/or thermal insulation. Damage to the building is automatic! The correct processing of the materials is a prerequisite for them to operate properly.