Sound damping

Vibration damping, also known as structure-borne sound damping or sound deadening, is primarily concerned with the reduction or muffling of emitted airborne sound.

If, for example, a hammer is used to make a gong vibrate, the sound that we hear is the airborne sound. However, it is not only airborne sound that is emitted when a material vibrates – the sound also propagates in the material/body itself (cf. impact sound). In order to reduce these vibrations and the associated sound propagation to a tolerable level in buildings, the vibration energy is absorbed, so to speak.

This problem arises in the case of sanitary installations, washing machines and ventilation systems in particular. The measures taken to solve it are mostly the same as those for impact sound and structureborne sound. Vibration damping is also used in the following areas:

- Sheet metal claddings

- Metal lamellae

- Plastic casings

- Lightweight walls

When damping a material, mass is just one factor that needs to be considered. The loss factor of the material or system is the most important aspect.

Good to know!

- Vibration damping is needed for thin-walled constructions

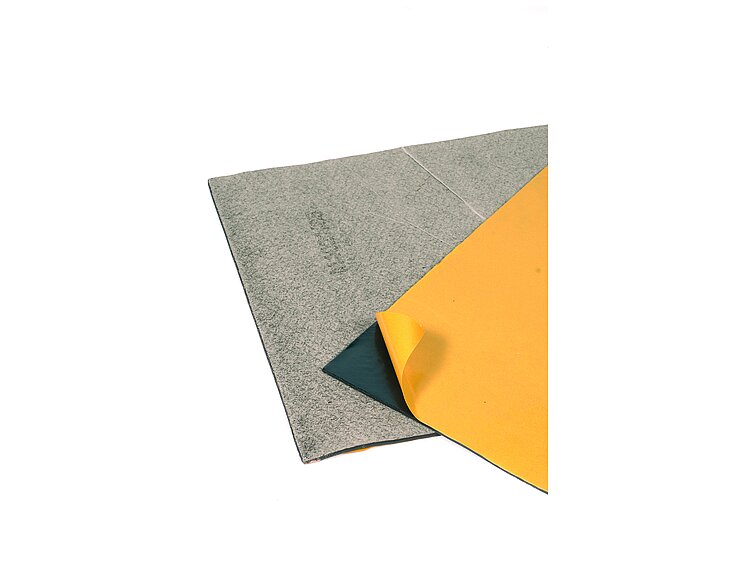

- Damping material is normally applied in double sheet thickness

- Vibration damping requires a full-surface bond between the two materials (damping material and the material to be dampened)

- Idikell in a lightweight construction insulates and dampens

Loss factor

The loss factor is a dimensionless variable which indicates how quickly the mechanically stimulated material settles down again. The higher the loss factor, the lower the sound propagation and the better the damping effect.

The loss factor is especially high in the case of very viscous heavy foils such as Idikell, making them particularly effective.