Airborne sound insulation

Airborne sound is noise that is carried through the air. Airborne noise is transmitted from outside of the building to the inside, as well as from floor to floor or from room to room, for example (i.e. within the building or unit).

Airborne sound insulation describes the act of reducing the passage of airborne sound by means of a separating element. The calculation is fairly simple. As shown in Figure 1, part of the incident sound energy (Ee) is reflected (Er) on the surface of the separating element (B) and part of it is absorbed by the separating element itself (Ea). Another part (Ed) escapes into the neighbouring room.

B separating element (ceiling, wall)

Ee incident energy

Er reflected energy

Ea absorbed energy

Ed emanating energy

The acoustic insulation capacity of a building component is described as sound reduction index R. R is a differential

value, i.e. the greater the value, the better the sound insulation. This value applies to the building component, but not to its

effect in a room. Airborne noise is not only transmitted directly through a separating element but also via adjacent elements (see Figure 2) – a phenomenon known as "flanking". The insulation effect of a building component can be recognised by the difference in the sound level between the transmitting room (sound level 1) and the receiving room (sound level 2), as shown in Figure 2.

This sound level difference depends on:

- Component properties

- transmission, reflection and absorption

- transmission, reflection and absorption

- Non-component-related properties

- Flanking

- Size and texture of the receiving room

Sound reduction index R

Indicates the airborne sound insulation of building components.

Measured sound reduction index R

Used when the sound is only conducted through the testing component, e.g. on a test bench with no flanking.

Apparent sound reduction index R'

Used for additional flanking or other indirect path transmission. The measurement can be performed on a test bench or in a completed building.

Nice to know!

Misinterpreting or failing to take into account the transmission of sound via flanking paths is a common planning error. Good planning of acoustics and sound insulation is just as important as major tasks such as installation, quality assurance and inspections during the construction phase.

Active principles

Mass (weight) of the component

For components with one component layer (single-layer components), the following basic principle applies: the heavier the component, the better the sound insulation. To increase the sound insulation of a component effectively, the increase in weight must be high in relation to the original weight. For example, if the aim is to improve the sound insulation of a 200 kg/m² concrete wall, the mass must be increased by at least 100 kg/m² – an increase of 10 kg/m² would have no effect.

Stiffness of component layers

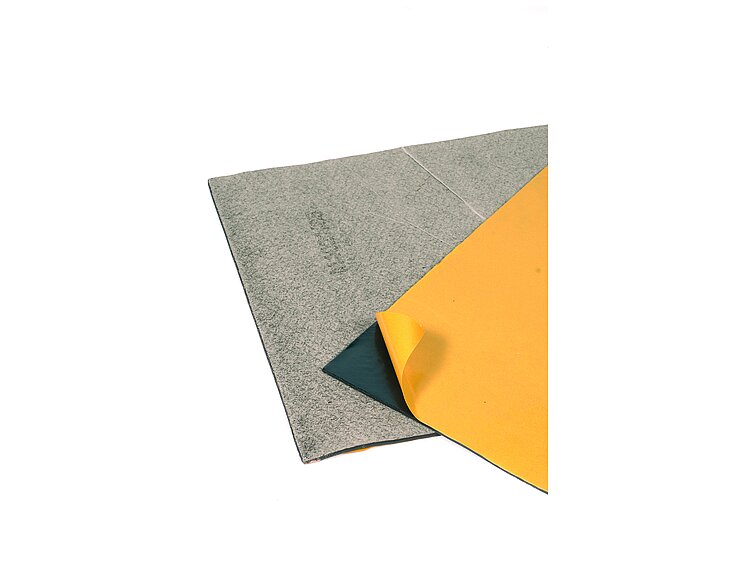

The sound insulation of a singlelayer component depends not only on the mass but also on the stiffness of the component. More rigid components have poorer sound insulation properties than softer components. It is not the stiffness of the material that makes the difference but, rather, the stiffness in combination with the material thickness that is used. For example, a steel sheet is flexible at a thickness of 1 mm, but rigid at 10 mm. In order to increase the sound insulation of a component, it is only necessary to increase the mass, not the bending stiffness. Additional mass will be the most effective if it is flexible. If, for example, one or two layers of Idikell are applied to a wood-based panel, it will not increase the bending stiffness by much.

Number of component layers

If individual layers are not mounted directly on top of one another but, instead, with a gap (air) between them, we refer to double- or multi-layer components. The heavier and more flexible the individual component layers are, and the greater the space between them, the better the sound insulation of the double-layer component will be.

Coupling of component layers

Double-layer components with no coupling of the component layers are fairly uncommon in a building. The technical term for unintentional coupling (i.e. due to a design fault) is "sound bridge". Poorly laid edge tiles on floating screed is a classic example of this. The acoustic insulation capacity of a component does not always behave completely "normal". There are two particularly important "deviations" from these active principles, which can lead to "unexplainable" airborne sound transmission. For many components, a decrease in sound insulation can be observed at frequencies between 2,000 and 4,000 Hz (coincidence). With double-layer constructions, there is also a clear reduction in airborne sound insulation at a certain frequency (doublewall resonance). Implementing noise protection measures in practice is very difficult. In addition to requiring detailed planning, the work must also be supervised on site. After all, adequate protection against noise is not only in the interest of the future occupants – it is also mandatory under the relevant standards. Whether a building complies with these standards or not can come down to the smallest detail.

Effective noise protection cannot be ensured by the component alone!

All factors should always be considered in practice. In order to understand what makes good sound insulation, it is necessary to understand some important basic principles:

- Mass (weight) of components

- Stiffness of component layers

- Number of component layers

- Coupling of component layers

In practice

Installing two layers of Idikell heavy foil reduces noise by half. Idikell is very thin and has a high surface weight. It is also flexible. Heavy foils are not only suitable for airborne sound insulation but also for vibration damping. The coincidence effect of many construction materials such as plywood, chipboard and plasterboard lies between 2,000 and 4,000 Hz – the exact range at which the human ear is most sensitive. As shown in Figure 1 on page 3, the auditory threshold of humans hits its lowest point between 2,000 and 4,000 Hz. Heavy foils reduce this coincidence effect by a massive amount.

Measures for airborne sound insulation

Suitable measures for improving sound insulation include:

- Decoupling the spaces

- The components stimulated by sound are fully separated from other spaces

- Decoupling the building components: limiting the room volume with soft-yielding mounted layers (e.g. using Ampaphon Z 600 vibration elements)

- Generally minimising the connecting elements

- Using Idikell heavy foils

- etc.

Example

The sound insulation of masonry, concrete walls or ceilings (i.e. components that are heavy and rigid from an acoustic point of view) is most effective when using facing shells. The facing shells unfurl their full potential when the panelling is heavy and flexible and the support structure is decoupled from the base wall. Flexible weighting of a panel (in the example: chipboard 16– 20 mm) with Idikell improves the soundproofing effect of a facing shell considerably. Optimum results (improvement: 10 dB) are achieved with simultaneous decoupling of the support battens by means of Ampaphon Z 600 vibration elements.

Nice to know!

Use screws with an appropriate length. Provide circumferential joints from 7 to 10 mm. Seal the joints with a suitable sealant. Ensure full air impermeability. It is not advisable to use synthetic insulation materials for sound insulation. The Idikell adhesive layer merely serves as an installation aid.