Ampatex Variano 3 extra

Moisture-variable vapour check and airtight layer, lattice-reinforced

Lattice-reinforced, three-layer moisture-variable vapour check and airtight-layer made of polyamide and polypropylene.

- Ideal for injection insulation due to its high tear resistance

- Over 59 m sD value range for maximum protection in buildings where moisture levels are critical

- Excellent adhesive properties

Lattice-reinforced, three-layer moisture-variable vapour check and airtight-layer made of polyamide and polypropylene. Perfectly suited for flat roofs in timber construction; also for renovating pitched roofs with a dense outer skin. The membrane offers special protection when used on bare brickwork in winter. Ideal for injection insulation due to its high tear resistance.

Conditions for the twenty-year premium warranty include registering the building object and the Ampack products used. In addition, our products must be used as part of a system. For further details, please see our General Warranty Conditions.

| Article number | Description | Roll dimensions |

|---|---|---|

7640442090578 | Ampatex Variano 3 extra with 60 lfm Ampacoll INT | 1,5 m × 50 m = 75 m2 |

| 7640442090431 | Ampatex Variano 3 extra | 1,5 m × 50 m = 75 m2 |

| Property | Value | Standard |

|---|---|---|

| Harmonised European Standard | EN 13984:2013 | |

|

Mass per unit area |

110 g/m2 |

EN 1849-2 |

|

Fire behaviour |

E | EN 13 501-1 / EN ISO 11925-2 |

|

Brandkennziffer |

5.2 | |

| Waterproofing | approved at 2 kPa | EN 1928 |

|

Water vapour permeability, sD value |

0,8 - 60 m | EN 1931 |

|

Width of overlap |

10 cm | |

|

Shear resistance of the joints |

130 N | |

|

Maximum tensile strength longitudinal / transverse |

300 / 250 N/5 cm |

EN 12 311-2, without support liner EN 13 859-1, Appendix A, with support liner |

|

Elongation longitudinal / transverse |

20 / 20 % |

EN 12 311-2, without support liner EN 13 859-1, Appendix A, with support liner |

|

Resistance to tearing (nail) longitudinal / transverse |

200 / 220 N |

EN 12 310-1 without support liner EN 13 859-1, Appendix B, with support liner |

| Resistance to alkalis | approved | EN 1847 |

| Air tightness | air tight | |

| Visible defects | none | EN 1850-2 |

| Values after artificial ageing | ||

|

Water vapour permeability, sD value |

approved | EN 1296, 70°C / EN 1931 |

Technical data sheets

|

|

Technical data sheet: Ampatex Variano 3 extra | Technical data sheet: Ampatex Variano 3 extra, moisture-variable vapour check and airtight layer |

Advertising media

|

|

Folder: Ampatex Variano 3 (extra) | Folder: Ampatex Variano 3 (extra), moisture-variable vapour check and airtight layer |

Declarations of performance

|

|

Declaration of performance: Ampatex Variano 3 extra | Declaration of performance: Ampatex Variano 3 extra 1,5 x 50 m, moisture-variable vapour check and airtight layer |

Tendering texts

|

|

Tendering text: Ampatex Variano 3 extra | Tendering text: Ampatex Variano 3 extra, moisture-variable vapour check and airtight layer |

|

|

Tendering text: Ampatex Variano 3 extra | Tendering text: Ampatex Variano 3 extra, moisture-variable vapour check and airtight layer |

Product inserts

|

|

Product insert: Ampatex Variano 3 extra | Product insert: Ampatex Variano 3 extra 1.5 x 50 m, moisture-variable vapour check and airtight layer, with Ampacoll INT |

|

|

Product insert: Ampatex Variano 3 extra | Product insert: Ampatex Variano 3 extra 1.5 x 50 m, moisture-variable vapour check and airtight layer |

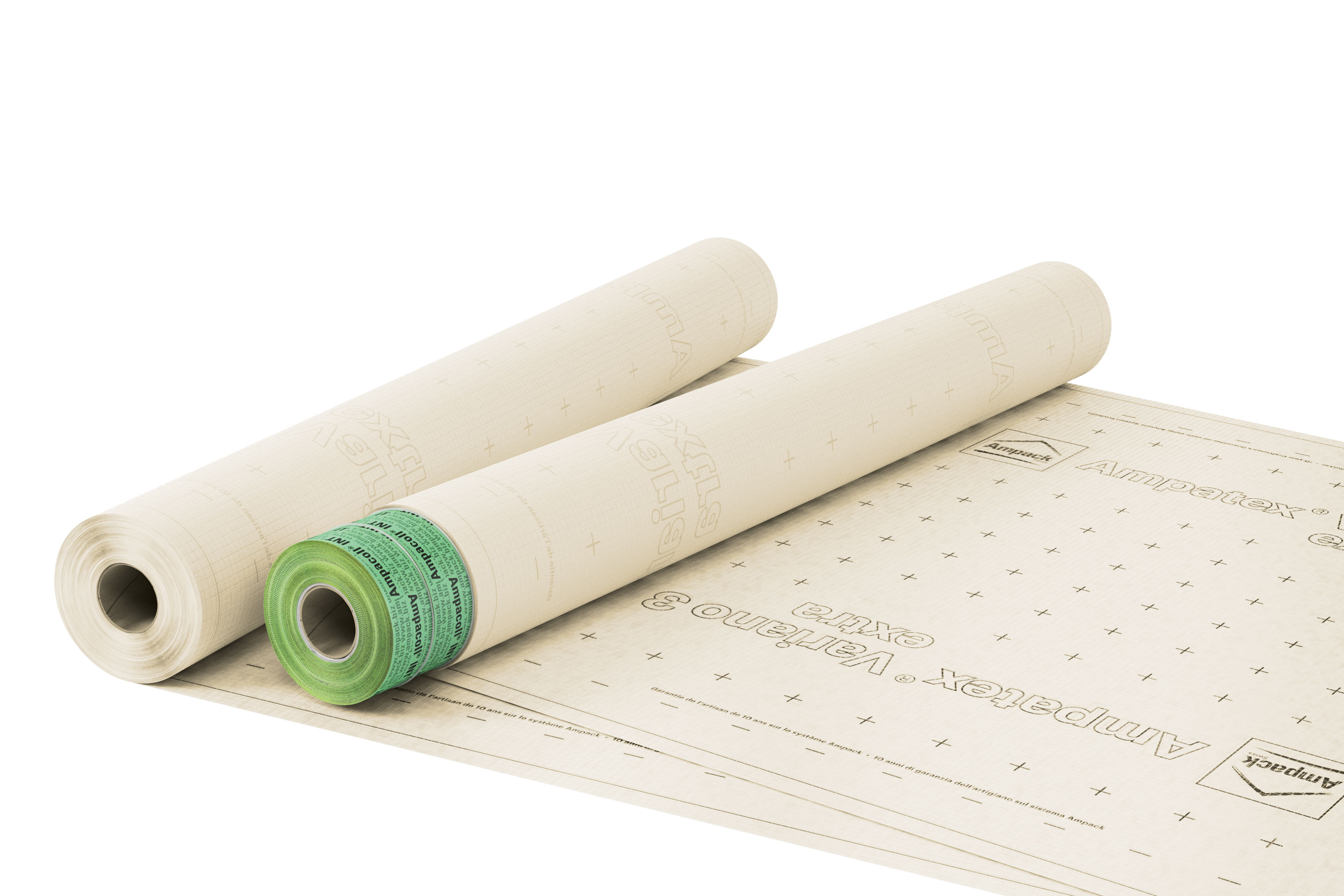

Product photos

|

|

Product photo: Ampatex Variano 3 extra | Product photo: Ampatex Variano 3 extra, moisture-variable vapour check and airtight layer, with Ampacoll INT |

|

|

Product photo: Ampatex Variano 3 extra | Product photo: Ampatex Variano 3 extra, moisture-variable vapour check and airtight layer |

Certificates

|

|

Certificate: Ampatex Variano 3 | ECO-Certificate ID 1119-34340-001: Ampatex Variano 3 |

Ampatex Variano 3 extra is applied as an airtight layer and moisture-variable vapour check for dry interior finishing and positioned on the warm side of the thermal insulation where it is stapled to the construction. Take care when positioning it that the membranes overlap by 10 cm and that the joints are tightly sealed with the enclosed system adhesive strip Ampacoll INT. Edge connections must be sealed with Ampacoll BK 530 or Ampacoll RA. Porous or dusty surfaces must be pretreated with Ampacoll Primax. Penetrations such as ventilation and electric pipes must be permanently sealed with Ampacoll BK 535 or Ampacoll Elektro u. Install sleeves. Humidity-variable materials can react to strong changes in ambient humidity. Consider shrinkage and expansion behaviour (e.g. conditioning on site, relief loops, mechanical securing, etc.).