Ampacoll RA

Edge connection adhesive

Solvent-free, airtight and durable elastic edge connection adhesive.

- Odourless – no solvent

- Primer not necessary

- Adheres to most surfaces

- Always easy to squeeze out

- Notched nozzle for a more even bead

Solvent-free, airtight and durable elastic edge connection adhesive. Perfect for use with vapour checks

and barriers.

Conditions for the twenty-year premium warranty include registering the building object and the Ampack products used. In addition, our products must be used as part of a system. For further details, please see our General Warranty Conditions.

| Article number | Content | Carton content | Content of pallets |

|---|---|---|---|

7640115530141 | 310 ml / cartridge | 12 cartridges | 125 cartons |

7640115530172 | 600 ml / tube | 10 tubes | 60 cartons |

| Property | Value | Standard |

|---|---|---|

|

Base Material |

Acrylate-copolymer | |

|

Storage |

frost-free, cool and dry | |

|

Durability |

> 20 years | |

|

Setting time |

2 to 3 days | |

|

Solvent |

none | |

|

Consumption |

30 – 50 ml / m | |

|

Operating temperature for product |

0 to +50 °C | |

|

Temperature resistance |

-20 to +80 °C |

Technical data sheets

|

|

Technical data sheet: Ampacoll RA | Technical data sheet: Ampacoll RA, liquid adhesive |

Safety data sheets

|

|

Safety data sheet: Ampacoll RA | Safety data sheet: Ampacoll RA, edge connection adhesive |

Product photos

|

|

Product photo: Ampacoll RA | Product photo: Ampacoll RA, liquid adhesive |

|

|

Product photo: Ampacoll RA | Product photo: Ampacoll RA, liquid adhesive |

Application photos

|

|

Application photo: Ampacoll RA cartridge | Application photo: Ampacoll RA cartridge, liquid adhesive |

Certificates

|

|

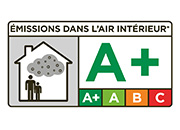

Certificate: Ampacoll RA | Certificate VOC: Ampacoll RA |

The substrate or surface must be sound, clean, dry and free of dust and grease. Continuously apply an 8 to 10 mm thick bead

to the substrate. Any dimples should be evened out with additional material. Vapor barriers or seals should be lightly pressed

onto the bead, without pressing it flat. Drying time 2 – 3 days. A short airing time improves the initial bonding.

This technique allows a tension-free installation without the use of an edge slat. Based on our experience and the recommendations made in the standards, safety issues should be carefully considered. In many cases edge slats also provide a fixing for internal cladding.